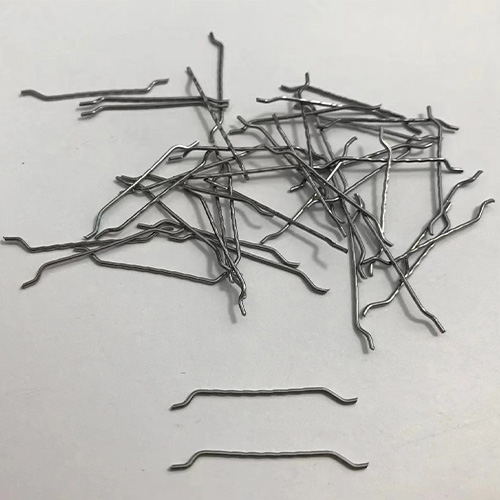

Monofilament Polypropylene Fibers for Anti-Crack

Length: 6mm/12mm/19mm(Support Customization)

Breaking Strength: ≥560MPa

Elastic Modulus: ≥3500MPa

Acid and Alkali Resistant: 96%

Melting Point: 160-180℃

Density: 0.91g/cm³

Hyperion monofilament polypropylene fibers, also known as anti-crack fibers, PP fibers, is a high-strength bundle fiber made of polypropylene with a unique production process. When added to concrete or mortar, it can effectively control microcracks caused by factors such as solid-plastic shrinkage, and temperature changes in concrete (mortar), prevent and inhibit the formation of cracks, and greatly improve the crack resistance and impermeability of concrete, as well as its impact resistance and seismic resistance.

Benefits:

1. Provides design and technical support based on your concrete performance requirements.

2. Increases the strength, durability and corrosion resistance of concrete -extend life-span.

3. Increases the abrasion and impact protection of concrete.

4. Environmentally friendly -building a greener and more sustainable future.

Applications of Hyperion Monofilament Polypropylene Fibers:

Monofilament polypropylene fibers can be widely used in the overlay of bridge decks and roads, mining and tunnel engineering, railways, high-rise buildings, fire prevention facilities, concrete repair, waterproofing projects of roofs.

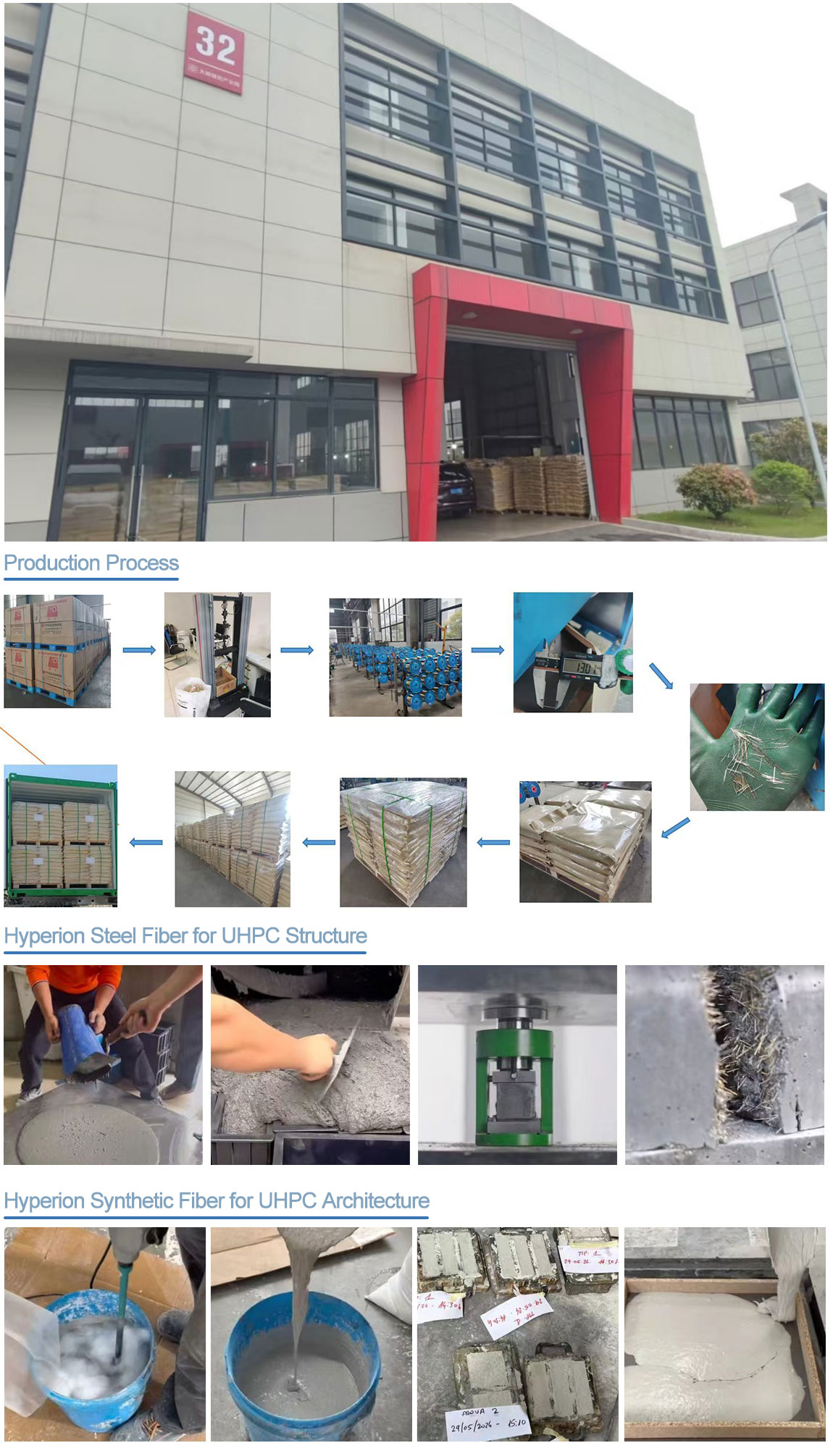

About Hyperion Fiber Ltd Profile:

About Hyperion Fiber Ltd Profile:

Hyperion Fiber Ltd is specialized in manufacturing high-performance Steel Fibers for UHPC, stainless steel fibers for UHPC, Innovated synthetic fiber for UHPC and innovative Polyolefin Fibers for ECC and fiber reinforced concrete(FRC) etc, which comply with EN14889-1 2006 and ASTM A820 standard.

We have more than 16 years of experiences in UHPC industry, with strong R&D team and UHPC consultants team and annual output of around 18,000 tons, manufacturing for more than 20 trading companies in China and abroad.

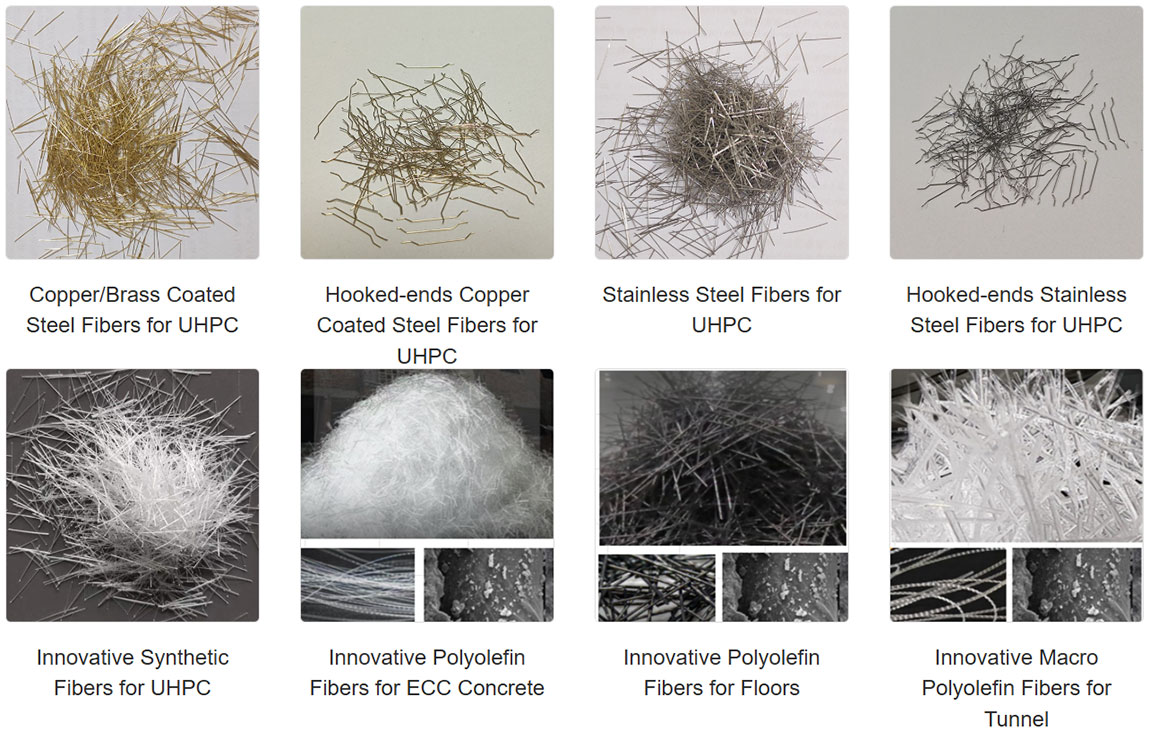

About Hyperion Fiber Series:

1). High-performance Steel Fiber for UHPC -More than 2800MPa tensile strength.

2). Innovative Synthetic Fiber for UHPC -Lower around 45% fiber cost than PVA fiber.

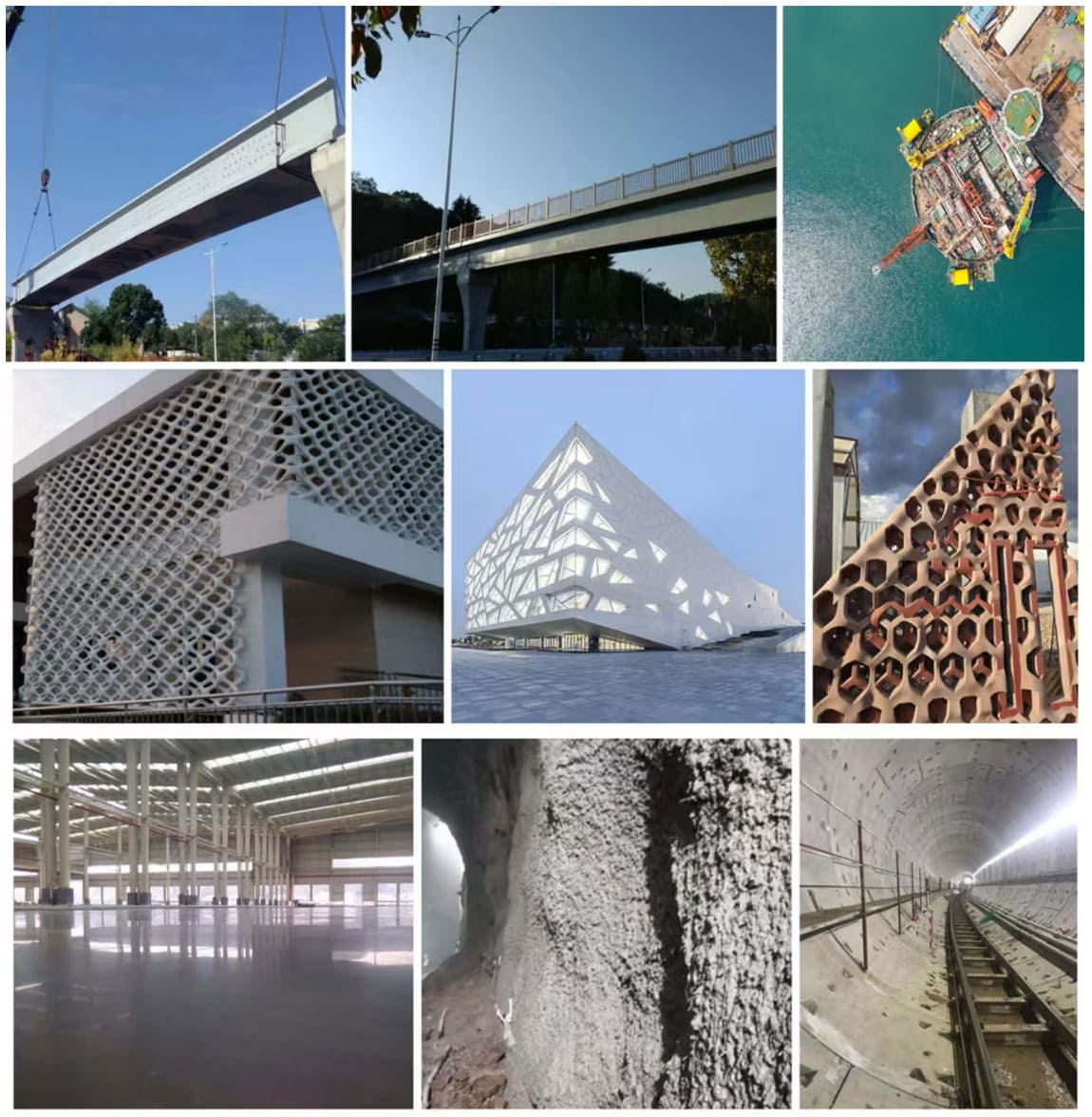

About Hyperion Fiber Series Application:

1). UHPC structure concrete, such as joint connections, overlays, girders and precast elements.

2). UHPC architecture concrete, such as facade, cladding, wall panels and urban furniture.

3). Steel fiber reinforced concrete, such as floors, tunnel.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Kevin

Phone: +86 17727969732

E-mail: kevin@hyperionmaterial.com

Whatsapp: +8617727969732

Add: Block R2-B, Gaoxin South Road, Gaoxin Community, Yuehai Street, Nanshan District, Shenzhen